Based on analytics, the majority of visitors come to my blog looking at my mechanical keyboard posts. Even though they are many years old at this point, my UT47.2, Tofu HHKB vs Tokyo 60 and 1UP Keyboards HHKB reviews still bring the most traffic to this blog. It’s crazy, are there not enough reviews of those keyboards on the internet? Who knows. The funny thing is, I don’t get comments on those posts so I’m not sure if people find them helpful.

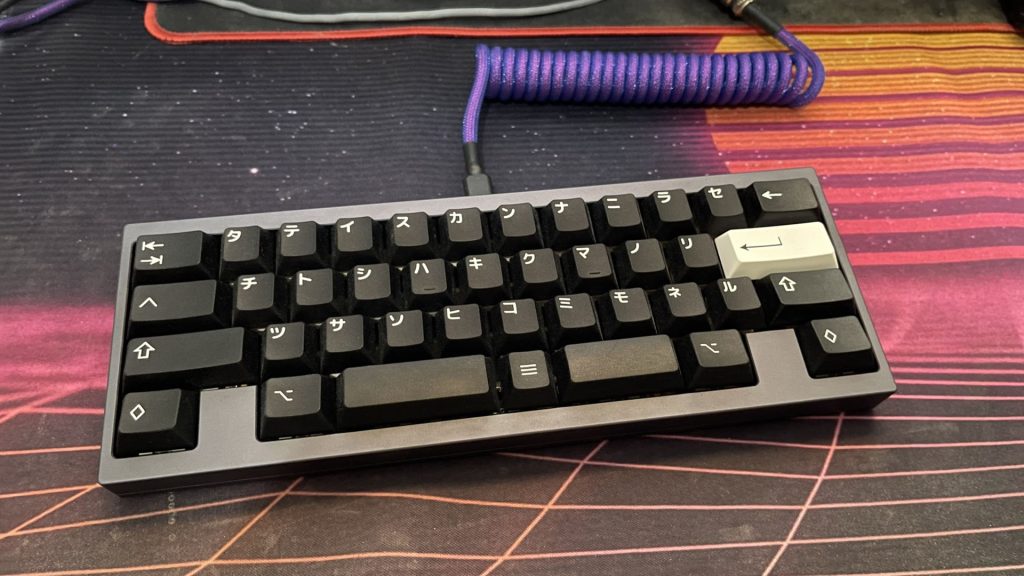

This means if I wanted to increase the number of viewers to my blog, I should write more about keyboards. However, my involvement in the hobby has slowly waned over the years. It’s not that I’m done with the hobby – my tastes/interests have been honed to the point where I’m only interested in 40% keyboards. Since it’s not the most popular segment of an already niche hobby, there’s not much to keep up with (which I’m thankful for – it’s been a blessing for my wallet and time).

That being said, I could spend a lot of time talking about how much I love using 40% keyboards. Would it be boring or irrelevant for most readers? Probably but I would be writing about something I care about. I’m not claiming to be the authority on all things 40% but as an enthusiast for the past four years, I know enough to provide intelligent answers.

I reached out to my friends, compiled some questions about 40% keyboards and will answer them in this post.

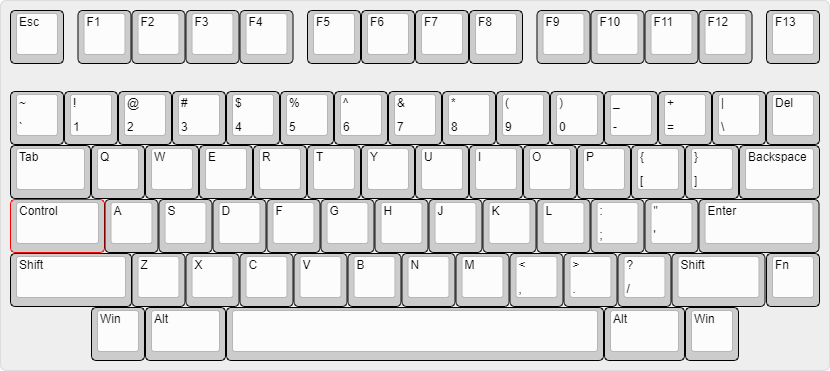

Where are your numbers? I could never use such a thing!

How do you remember where your capital letters are? It’s really the same thing. But instead of pressing shift, you use a different button. If you think of it that way, you’re halfway there to using a 40%.

In fact, most people have already been using 40% keyboards for a while – think of the keyboard on your smartphone. Almost all the symbols are hidden behind a layer key. It’s the same thing here, with the only difference being you’re typing on a much smaller keyboard.

Is there any other point of 40% other than portability? Why do you inconvenience yourself by using such a small keyboard?

The main reason I got myself a small keyboard was to make travelling with one easier. I used to lug around my full-sized to work before I got into smaller form factors. Bringing such a large device around was a hassle, especially when working out of cafes that had tiny desks. I knew I needed something smaller.

Small keyboards give you the joy of typing on mechanical switches without taking up too much space (on your table or in your bag). That’s my main reason for using a 40%. After getting used to the layout, it turned out to be a blessing in disguise. It no longer became an inconvenience.

Being able to hit every key I needed without stretching was a game-changer for me. I enjoyed it so much that my 75% at home has a 40% layout mapped out to its keys. I only use the redundant keys when typing with one hand.

Should I use a 40% keyboard?

I don’t think everyone needs to use a 40% keyboard but if the opportunity presents itself, I’d recommend trying it out. There’s no harm if you discover it’s not for you. But if you do give it a shot, don’t give up after a day or two. It’s not something you ‘get’ right away and will require some effort. Use it daily for a few weeks before you make up your mind.

If you’re content with what you have and don’t need to downsize your keyboard because you don’t travel much/work away from your desk or you’re happy with your laptop’s keyboard, there’s no reason to try a new form factor unless you’re feeling curious or adventurous. Or you like its aesthetics.

Do people just instinctively know where to press for what keys and layers etc, after a while of using them? Or is there an easier way to remember for beginners? Like a layout chart or something?

For me, it wasn’t instinctive. I had to learn the hard way. Fortunately, my first 40% keyboard, the Vortex Core had side printed keycaps that helped with the transition. For the first few days, I kept looking at the keyboard to make sure I was hitting the right keys. However, that didn’t last long. Once I started remapping the default layout, the keycaps didn’t match them anymore, so I had to rely on my memory. I also saved images of my layout on my desktop.

I used a Vortex Core in the beginning which eased the transition – but couldn’t rely on the keycaps after a while when I started mapping my own layout. Completely ditched them in the end but I did rely on screenshots/images of the layout I saved on my desktop. I used the same technique for some of the keyboards I got after the Core, but after a few months, I didn’t need them anymore (all my 40% keyboards have very similar keymaps).

What are the 2 space bars for?

I use left for space and right for activating a layer. When first moving to 40% keyboards, I paid attention to which thumb I used for the space bar and learnt that I always hit with the left one. This was an easy decision for me to make.

Having a function key for the right bar is something I picked up from using the Core. Since it felt natural to use, I haven’t bothered changing it. I know some people bind it to backspace or enter, and that’s the magic of QMK (or programmable keyboards), you can make it whatever you want it to be.

This wraps up the first part of my 40% FAQ. I’ve got more posts lined up on the topic – questions from a hobbyist perspective and an explanation of my 40% keymap, stay tuned!